It should be noted that the laser system requires less than 25 seconds on average to lock onto each other and begins transmission in both directions at 5.6 Gbit/s. The fiber technology has been tested: “the two spacecraft were in a line of sight from each other, an average of about 20 minutes during which the laser beam link between them turned about 80°.”

Herewith, NASA demonstrated the first fiber laser connection in deep space when its laser system device provided data transmission from the Moon at 622 Mbit/s. The laser technology offers a big improvement over data rates real with radio waves. The first commercial laser system inter-satellite link was performed in 2016 resulting in the transmission of high-priority image data collected by four satellites in low-Earth orbit at rates of 1.8 Gbit/s.

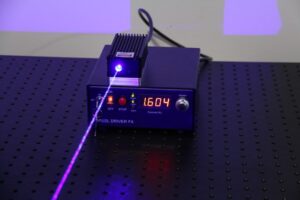

To be more precise, the high-speed fiber laser system in the low satellite allows tracking the geosynchronous satellite, that is why it can transmit images quickly, without the necessity to wait to pass over a ground station. Also, its high-speed fiber laser connection enables transmitting images to cloud servers on the ground. Herewith, a totally new vision has appeared for laser system link in space: applying fiber laser-connected satellites in low-Earth orbit to transmit broadband Internet and other services to places beyond the reach of fiber optic cables.

Hundreds or thousands of small satellites are orbited 300 and 2000 km above the ground, while at least one satellite should be always in the sky above any point being served. Moreover, these satellites would orbit around the Earth in several rings, located at various altitudes and positions to get rid of collisions. Thus, satellites would be located around each ring so fiber laser system connections would always have access to one or two adjacent satellites.

Finally, links provided by fiber lasers have crucial benefits over radio frequencies for inter-satellite links above the atmosphere, for instance, higher transmission bandwidth, smaller receivers, and tighter laser beams to enhance security. The main difficulty in the optical fiber band remains and includes the requirement to maintain fiber laser links between adjacent satellites as the whole constellation moves through space and the nearest neighbors of each satellite keep changing.

Optromix is a fast-growing fiber laser manufacturer and a vendor of optical fiber sensors and optical monitoring systems. The company offers fast turnkey solutions and creates sophisticated fiber laser systems for special purposes. Optromix uses only its technologies and develops a broad variety of fiber lasers. If you have any questions or would like to buy a laser system, please contact us at info@optromix.com